Introduction – what are Scope 3 Category 12 emissions?

Scope 3 Category 12 refers to the emissions associated with the end-of-life (EOL) treatment of products that a company sells, once they are discarded or otherwise disposed of by the consumer. For retailers, measuring these emissions is crucial, especially in the context of growing expectations for businesses to report on environmental impact comprehensively.

End-of-life emissions encompass processes such as waste collection, sorting, recycling, incineration, and landfill. These activities can vary significantly based on the product type, local recycling capabilities, and disposal practices. For accurate reporting, you would need to estimate these emissions based on the best available data and methodologies.

This chapter focuses on how you can measure and improve the accuracy of your EOL emissions, particularly for products sold to consumers, and suggests ways to refine the data over time using existing information.

Estimating End-of-Life Emissions: The Basics

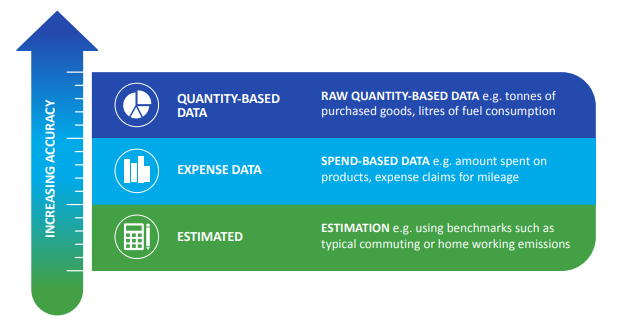

To measure end-of-life emissions effectively, you may use several approaches. The most straightforward method is to estimate emissions based on the tonnage of products sold. However, more accurate calculations can be achieved by leveraging additional data that may already be available through supply chain partners, consumers, and industry-specific information.

Tonnage-Based Estimations:

- Basic approach: The first step is to estimate emissions based on the total mass of products, including packaging, sold during the reporting period. This estimate is generally calculated by multiplying the total tonnage of products by an associated emissions factor (gCO2e per kg of product) for different disposal routes (landfill, recycling, incineration, etc.).

Example:

- Your company sold 10,000 tons of clothing in a given year.

- Estimated disposal breakdown:

- 50% recycled

- 30% landfilled

- 20% incinerated

- Emission factors:

- Recycling: -0.5 tons CO2e/ton

- Landfilling: 1.5 tons CO2e/ton

- Incineration: 2.0 tons CO2e/ton

Using these factors, the total estimated emissions from end-of-life disposal would be:

- Recycling: 10,000 tons × 50% × 0.1 = -500 t CO2e (

- Landfilling: 10,000 tons × 30% × 1.5 = 4,500 t CO2e

- Incineration: 10,000 tons × 20% × 2.0 = 4,000 t CO2e

Total emissions: 4,500 + 4,000 +500 = 9,000 t CO2e

- Data needed: The product's weight, end-of-life disposal mix in region of sale, and the appropriate emissions factors.

Emission Factors and Disposal Routes:

- The emissions associated with end-of-life disposal depend on the final treatment of the product. Common disposal routes and their approximate emission factors are as follows:

- Landfill: High emissions due to methane generation (especially for biogenic materials), though can be reduced if biogas capture takes place at the landfill.

- Incineration: Emissions from burning, depending on fuel types and waste composition. Can be reduced if energy capture takes place, displacing grid electricity.

- Recycling: Lower emissions, usually only accounting for emissions from transport and processing of the waste. Cuts off any emissions from the subsequent processing into a new material.

- Composting: Similar to landfill but lower methane emissions for biodegradable products.

You should ideally estimate the percentage of products disposed of, through each treatment type based on the waste management practices in the regions where the products are sold, for the type of waste that your product represents.

Refining Accuracy: Beyond Basic Estimation

To improve the accuracy of Scope 3 Category 12 emissions, you need to access and integrate more granular data. There are several strategies you can adopt to refine your estimations:

Detailed Product Data:

- Product composition: You can analyse the material composition of your products to estimate the likely EOL disposal route more accurately. For example, products made of plastic may more likely be incinerated or landfilled, while those made of metal or paper are more likely to be recycled.

- EOL pathways per product type: Products vary significantly in terms of their EOL pathways. For retailers selling garden products, for example, it is possible to use more specific data about relevant recycling programs and rates.

Collaborating with supply chain partners:

- You can collaborate with manufacturers, waste management firms, and logistics partners to gather more detailed data about the disposal and recycling rates for your products. This data can include:

- Specific recycling rates for materials (e.g., percentage of plastics, paper, or metals recycled)

- Local recycling and landfill practices

- Data on regional incineration practices and associated emissions factors.

- Some manufacturers already incorporate end-of-life data into their product design, allowing retailers to improve their estimates.

Consumer behaviour and reporting:

- Consumer feedback: You may also use customer behaviour data to refine your emissions models. For instance, offering incentives for customers to recycle products (e.g., take-back schemes) or tracking returns and recycling rates may provide valuable insights into the EOL treatment. The former would also help to reduce your end of life emissions.

- Take-back programs: You may set up take-back programs, enabling you to collect products at their end of life, recycle them, or send them for responsible disposal. Data from these programs can be used to report emissions more accurately by understanding what happens to products after their use.

- Waste audits: If feasible, you could commission research or work with third-party organizations to assess the types of products being discarded by consumers and determine their disposal routes.

Leveraging digital tools and databases:

- Emission factor databases: Several organizations and databases offer detailed emissions factors tailored to various types of products and their end-of-life treatment. You can subscribe to or partner with these databases for more precise emission factor data.

- Life Cycle Assessment (LCA) software: LCA tools can provide more detailed insights into the full lifecycle of a product, including end-of-life emissions. By incorporating these into your operations, you can use LCA results to better understand and report your Scope 3 emissions.

Best Practices: Improving Accuracy Over Time

The accuracy of end-of-life emissions estimates improves over time with better data, improved estimation methodologies, and more advanced tools. Here are some steps you can take to improve your Scope 3 Category 12 accuracy:

- Start simple, then gradually integrate more data:

- Begin with basic tonnage-based estimations and use general emissions factors. Over time, as more accurate product and disposal data become available, integrate these into the estimation model.

- Use data from previous years:

- Retrospective analysis using historical sales data and product disposal trends can help improve accuracy and set baselines for future estimations.

- Regularly update emissions factors:

- Stay up to date with new research and updated emissions factors, particularly as recycling technologies and landfill management improve.

Conclusion

Measuring end-of-life disposal emissions is a critical aspect of Scope 3 Category 12. While initial estimates can be made based on total product tonnage and generic emissions factors, leveraging more detailed product data, collaborating with supply chain partners, and utilizing consumer feedback can significantly improve the accuracy of these estimates. Over time, you should aim to refine your approaches by incorporating more granular and region-specific data, leading to more accurate and actionable emissions reporting.